"Honey, can we buy a new car?"

"Go look in the garage, I just printed out a new Porsche last night."

"I hope it's the right color."

"Let me know, because we can change it today if you prefer."

Is it really going to be that easy when 3D printing technology takes over the car manufacturing industry? If you ask many experts, it will be here sooner than you think. In fact, next year a company called Local Motors will enable you to purchase a brand new vehicle online that can be printed within less than two days, and then shipped directly to your home or business.

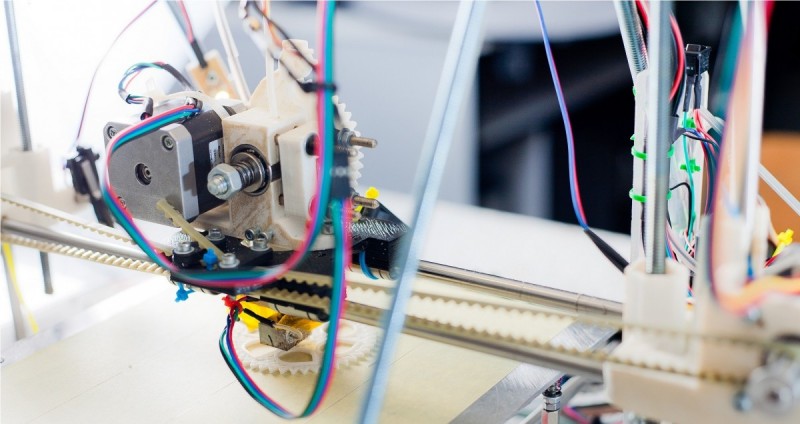

A decade ago, 3D printing (also known as additive manufacturing) impressed people by producing small parts like whistles and children's toys. Now, huge corporations are taking note and investing big money in this technology.

3D printing has already created new amazing opportunities for companies that fix and restore cars, or that manufacture parts or accessories for them. It presents car manufacturers with so many options for new designs, while the car restoration industry is also taking advantage of this technology.

Manufacturers are already printing vehicles from scratch. One such vehicle is the Strati, the world's first 3D-printed electric car. It was manufactured using a large scale 3D printer developed by a partnership between ORNL and Cincinnati, Inc. almost three years ago. The car took only 44 hours to print, which was followed by three days of milling and assembling, followed by a series of successful test drives.

Other cars made with 3D printing technology include the Urbee, the first car in the world that had body panels and windows that were 3D-printed. Created by a Canadian company called KOR Ecologic, it's a hybrid vehicle that is environmentally sustainable and currently headed for mass production.

Similarly, companies such as Divergent 3D in San Francisco, CA are aggressively setting out to prove that 3D printing can make cars more affordable and efficient.

There is also a wide range of other 3D-printed cars that start-ups and established companies are manufacturing with great names, such as The Blade (made by Divergent), Micro Commuter, GENESIS, Soulmate, KIA Telluride and the Delage Type-S, just to name a few.

The first industry that will be affected significantly by 3D technology is the parts manufacturing segment. Now the whole debate of O.E. vs. aftermarket parts is going to change in a big way. Parts providers won't need huge warehouses anymore, or to maintain enormous inventories, because they will be able to print parts on demand. It will be crucial for the auto restoration industry as well, because if a part isn't available for a classic car, all you have to do is print one.

The interest in mass producing cars via 3D-Printing has gradually gone from a small inkling to a sudden explosion of interest. I predict that by next year, we will see cars that have more than 40% of their parts printed via 3D technology and within 3-4 years, 3D-printed cars will be available at dealerships. First, only wealthy people will be able to afford them, but once the technology becomes more accessible and more sophisticated, you and I will be able to own one too.

With every type of new technology, 3D printing will find new applications along the way and the automotive industry will be right there in the middle of it all. It will create new jobs and better products, and society will benefit across the board. 3D printing is here to stay, so if you're in the automotive industry in any capacity, get ready for a fun and exciting ride!